CORES

COMPOUND CORESThe Key to Lightweight and Strong Structures in Diverse Industrial Sectors

Core composites play a key role in the manufacture of lightweight and strong composite structures. These materials are used as internal filler or reinforcement, providing additional stiffness and strength without adding significant weight. Core composites are widely used in sectors such as shipbuilding, aerospace and building panel manufacturing, enabling the creation of efficient, durable and high-performance structures.

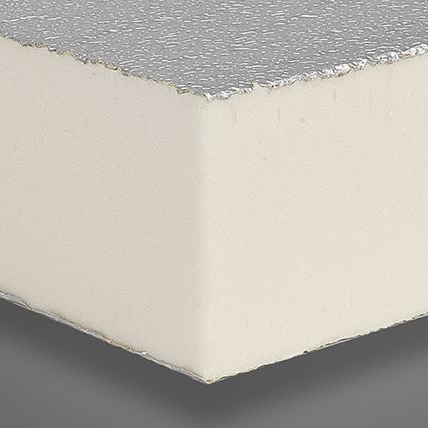

We offer you rigid polyurethane foam (PUR) sheets cut and machined from a block of the material.

They are available in 2000 x 1000 mm and 2500 x 1000 mm sizes, with densities of 40, 70, 100, 180 and 280 kg/m2 and thicknesses from 10 to 500 mm.

Other dimensions on request

Properties:

- Reduced insulation thickness due to the low thermal conductivity coefficient of the polyurethane foam.

- High stiffness and low weight panels

- Virtually no water absorption due to closed-cell polymer structure

- Ease of machining and cutting

Applications:

- Thermal insulation for the construction of refrigerated trucks

- Thermal insulation of cold room floors and freezing tunnels.

- Thermal insulation in sandwich panels with metallic sheet, polyester, wood, fiber cement, etc.

- Working temperature range: +80ºC to negative temperatures.

PIR foam is a variant of polyurethane foam and is practically the same in terms of appearance, properties and insulation coefficient, with the difference being that PIR has a higher resistance to fire and temperature.

They are available in sizes 2500 x 1000 mm in any thickness.

Other dimensions on request

Properties:

- Reduced insulation thickness due to the low thermal conductivity coefficient of the polyurethane foam.

- High stiffness and low weight panels

- Virtually no water absorption due to closed-cell polymer structure

- Ease of machining and cutting

- Improved fire performance compared to PUR foam

Applications:

- Thermal insulation of cold storage and tunnel floors

- Thermal insulation in sandwich panels

- Pipe and pump support, machined in the form of half shells

- Used in the construction of railroad interior parts.

Recommended as a core in a sandwich panel structure, for parts requiring high performance.

Properties:

- Adaptable to all types of surfaces

- Resistant to extreme temperatures: from – 200 ºC to + 70ºC.

- Low resin absorption

- Low specific weight

- Low impermeability under pressure to liquids (sea water, fuels, animal oils, etc.)

Applications:

Marine, automotive, wind energy, aeronautics.

Designed for manual molding of GRP parts, reducing the lamination time, weight and cost of the parts, and making them lighter and stiffer with less glass and resin content.

Properties:

- Provides high impact resistance and good insulating properties

- Reduces surface etching of roving and other cores.

- Low density

- Good mold adaptability

- Reduces resin consumption by 15% to 20%.

- Compatible with polyester, vinylester and epoxy resins

Applications:

Nautical, industrial parts, etc.