FIBERGLASS

FIBERGLASS COMPOSITESDiscover the Versatility of Fiber Glass

Fiberglass is a versatile and resistant material that finds applications in various sectors. Known for its high mechanical strength and insulating capacity, it is used in the manufacture of automotive components, ships, aircraft and housing construction. It is also widely used in the wind energy industry, pipe manufacturing and in the production of sports equipment and consumer products.

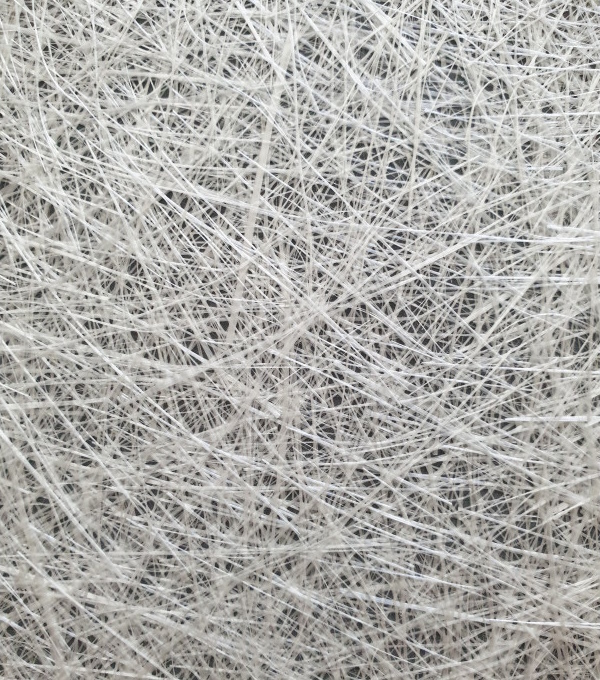

Type E glass, with weights from 100 to 900 gr. /m2, and widths from 100 to 3500 mm, manufactured from 50 mm long glass filaments, randomly distributed to form a regular base and bonded together with an emulsion or powder binder, soluble in styrene, depending on the application to be given.

Properties:

Mat Emulsion:

- Good resin impregnation, especially in manual processes, avoiding the formation of bubbles.

- Compatible with vinylester, bisphenolic, epoxy and phenolic resins.

Mat Powder:

- Very good impregnation.

- Ideal for continuous processes.

- Good corrosion resistance

- Suitable for chemical barrier construction

- Compatible with vinylester, bisphenolic, epoxy and phenolic resins

Applications:

Nautical, manual processes, automotive, piping, etc.

3-layer reinforcement mat alternating 2 layers of fiberglass with 1 layer of synthetic polypropylene material. It presents several typologies that we put at your disposal

- RTM 300/180/300 – RTM 300/250/300

- RTM 450/180/450 – RTM 450/250/450

- RTM 600/180/600 – RTM 600/250/600

Properties:

- High deformation capacity that allows an optimal adaptation to the mold.

- Fast resin diffusion.

- Compressible material. They adapt well to molds of various thicknesses.

- Good mechanical characteristics.

- This material is free of stringing, which allows for a quick setting of its fibers.

Applications:

Specially designed for RTM and RTM Light processes.

Manufactured from E-glass yarns with uniform weft.

We offer grammages from 100 to 1500 gr/m2, in different widths.

Properties:

- Provides high mechanical performance

- Compatible with polyester, bisphenolic, vinylester and epoxy resins.

Applications:

Mainly used in manual processes. Nautical, swimming pools, tanks, bodywork, furniture and in any application requiring higher mechanical resistance and lower weight.

PROJECTION

Formed by continuous strands of type E glass, in 2400 tex, joined without mechanical torsion. Each yarn consists of numerous monofilaments, bonded together with a splicing compatible with polyester and vinylester resins.

Properties:

- Good shearing behavior

- Weak blade wear

- Excellent mold impregnation

Applications:

Molds of large dimensions such as storage tanks, cooling towers, automotive parts, swimming pools, purification filters, etc.

DIRECT

Formed by continuous strands of type E glass, joined together without mechanical twisting in a single strand. Available from 1100 to 9600 tex.

Properties:

- Optimum compatibility with most polyester, vinylester, epoxy and phenolic resins

- Rapid impregnation

- Easy Handling

- Good abrasion resistance

- High filament strength

Applications:

Suitable for continuous processes such as pultrusion, winding (FW), and

fabric manufacturing.

Complex formed by mat and roving fabric

We have the following typology available in standard width of 1250 mm

- Mat 300gr/m2 + fabric 300 gr/m2

- Mat 300/450 gr/m2 + fabric 500 gr/m2

- Mat 300/450 gr/m2 + fabric 800 gr/m2

- Mat 300/450 gr/m2 + fabric 800 gr/m2 + Mat 300/450 gr/m2

Other combinations and widths on request.

Properties:

- Compatible with polyester, vinylester, phenolic and epoxy resins.

- Savings in resin consumption and application time

Applications:

Specially used in manual processes, nautical industry, automotive industry,

laminated panels, pultrusion.

A randomly dispersed and arranged C-type glass fiber web, bonded by an emulsion binder compatible with polyester, vinylester and epoxy resins and used as a surface coating on glass fiber reinforced plastic parts to improve their chemical resistance and finish.

We have a standard weight of 30 gr/m2, and width 1000 mm (other weights and widths, upon request).

Properties:

- Uniform fiber dispersion.

- Smooth surface and with low content of silting.

- High resin impregnation, which confers good chemical resistance.

- Optimum behavior in the mold.

MULTIAXIALS

Fiberglass reinforcement for composites, manufactured with fibers arranged unidirectionally in different layers of varying weight and orientation, stitched together to form a single reinforcement:

Properties:

- Better adaptation to the mold

- Increased rigidity

- Improved impact resistance

- Lower resin consumption

- Increased impregnation capacity

- Resin savings

Applications:

All types of wind turbine parts, automotive parts, etc.

THREE-DIMENSIONAL

3D FABRIC consists of two bi-directional woven fiberglass fabric surfaces, joined together by vertical threads that intertwine with each other.

We have a range of thicknesses from 3 to 50 mm, and widths up to a maximum of 1,270 mm.

Properties:

- High resistance to lamination.

- Good anchorage between the different layers

- Impact resistance

- Provides great lightness to the part

- Excellent thermal and acoustic insulation.

Applications:

Manufacture of double-walled tanks, parts for the automotive, railroad, wind energy, nautical and construction industries.

SILIONE

They are mainly used for laminating with epoxy resin systems and sometimes with vinylester and polyester. Excellent mechanical properties are obtained with very low laminate thicknesses because this type of yarn allows a higher mass concentration in a smaller volume.

Weights: from 24 gr/m2 to 200 gr/m2.

Applications:

Surfboards, model airplanes, base plates.

CARBON

They are used for the manufacture of strong, rigid and lightweight structures. We have a wide range of formats and weights.

Properties:

- Low density.

- Better elastic modulus

- Tensile, compressive and corrosion resistance

- Excellent electrical conductivity

Applications:

Automotive, nautical, aeronautical.

ARAMIDA

Properties:

- High impact resistance.

- Low density.

- High resistance to fatigue and corrosion.

- Fire protection.

Grammages: 125 gr/m2 and 175 gr/m2.

Applications:

Protective equipment.

Fiberglass fabric in different widths

Properties:

- Compatible with all types of unsaturated polyester, phenolic and epoxy resins.

- Available in various designs with widths from 50 mm to 150 mm

- Roll length: 100 m

Applications:

Pipe coating, automotive and pultrusion parts